It is important to create a technically and technologically improved device that reduces the damage to the mung during the process of removing the pods from the currently cultivated mung grain. Therefore, it is necessary to develop the design of the device, to justify its parameters and operating modes, for the complete separation and preliminary cleaning of mung beans without damaging them. The article presents the results of optimization of the main design dimensions and operating modes of the device for separating mung bean from the pods. The results of experimental studies showed that the proposed device has a high degree of completeness in separating mung bean from its pods and a low level of damage, low grain damage and high grain purity, which can be ensured with a sag length of 170 mm, a shaft oscillation number of 300 min-1, the amplitude of the shaft is 11.5 mm, its angle of inclination is 12 degrees. The design of the device for preliminary cleaning of mung grain by separating it from pods has been developed. The scientific significance of the research results is based on the structural dimensions and operating modes, as well as the resulting analytical connections and mathematical models, to ensure the quality of initial cleaning, to separate mung beans from pods completely and without damage, using less energy and resources. can be used to justify the parameters of similar devices. The developed device reduces the consumption of energy and labor during the initial cleaning of mung grain from pods, as well as the loss of grain.

| Published in | Engineering and Applied Sciences (Volume 9, Issue 4) |

| DOI | 10.11648/j.eas.20240904.12 |

| Page(s) | 63-68 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2024. Published by Science Publishing Group |

Mung, Bean, Grain, Crusher, Device, Angle, Amplitude, Hopper

For the technological process of separating mung grains from pods | ||||||

|---|---|---|---|---|---|---|

Name of factors | Designation | Limit of change | Range of change | |||

Real | Coded | –1 | 0 | +1 | ||

Number of shaft revolutions, rpm | N | X1 | 300 | 350 | 400 | 50 |

Number of grains, pieces | Zk | X2 | 15 | 18 | 21 | 3 |

Length of studs, mm | l | X3 | 160 | 165 | 170 | 5 |

For the technological process of mung grain cleaning | ||||||

Number of drum vibrations, min-1 | nt | Y1 | 300 | 350 | 400 | 50 |

Amplitude of drum vibrations, mm | At | Y2 | 9 | 12 | 15 | 3 |

Angle of inclination of the kingpin, degrees | Αl | Y3 | 6 | 9 | 12 | 3 |

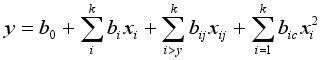

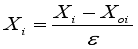

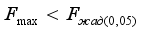

,(1)

,(1)  (2)

(2)  ,(3)

,(3) The name of indicators | Factors and their meanings | ||

|---|---|---|---|

n, r/min | Zk, pcs | l, mm | |

Conditional | +0,121 | 0 | +1 |

Real | 353,6 | 18 | 170 |

Rounded | 350 | 18 | 170 |

The name of indicators | Factors and their meanings | ||

|---|---|---|---|

Nt, min-1 | At, mm | αl, deg. | |

Conditional | 0 | -0,56 | 1 |

Real | 304,46 | 11,65 | 12 |

Rounded | 300 | 11,5 | 12 |

| [1] | Rosaboyev, A. T., & Pardayev, O. R. Energy and resource saver divices for development seed producing of the leguminous crops. Efficiency of application of innovative technologies and equipment in agriculture and water management. 2020, 74-77. |

| [2] | Mukhammedov, S., Khaydarov, A., & Pardaev, O. Quality control of baby food products on the basis of results obtained using the instrumental neutron-activation analysis technique. Uzbekiston Fizika Zhurnali. 2013, 15. |

| [3] | Lee, A. Technological bases of harvesting and equipment for lucerne seeds cleanings. Agricultural Machinery and Technologies. 2017, (6), 28-35. |

| [4] | Tukhtabayev, M. A., Pardaev, O. R. Moisture and hardness of the soybean stem. Mechanics and technology. 2021, 4(5), 67-73. |

| [5] | Rosaboev, A., & Mamadaliyev, A. Theoretical substantiation of parameters of the cup-shaped coating drums. International Journal of Advanced Research in Science, Engineering and Technology. 2019, 6(11), 11779-11783. |

| [6] | Tukhtamirzaevich, M. A. Results of laboratory-field testing of hairy seeds coated with mineral fertilizers. In Proceedings of International Educators Conference, 2022; 1(3), pp. 528-536. |

| [7] | Pardayev O. R., Achilov E. T. Optimizing the main structural dimensions and operating modes of the device that separtest the seeds of agricultural crops from the ears and pods. Economics and society. 2023, 3(106), 172-175. |

| [8] | Astanakulov, K. D., Babaev, K. M., Eshankulov, K. M., & Turdibekov, I. M. Development of technology and equipment for harvesting mung bean crops. In IOP Conference Series: Earth and Environmental Science, Tashkent, Uzbekistan, 2022, 1112(1), pp. 012008, |

| [9] | Astanakulov K D, Rasulov A D, Baimakhanov K A, Eshankulov Kh M and Kurbanov A J. Important phys-ical and mechanical properties of the mung bean seed for harvesting and cleaning process. In IOP Conference Series: Earth and Environmental Science, Tashkent, Uzbekistan, 2021; 848, pp. 012171. |

| [10] | Rasulov, A., Abduraxmanov, A., Igamberdiev, D., & Idrisov, K. Primary Cleaning Machine for Small and Medium-Sized Mung Bean Grains for Farms and Peasant Farms. In BIO Web of Conferences, Tashkent, Uzbekistan, 2023; 78, pp. 06006. |

| [11] | Shomirzaev, M. K., & Umirov, A. T. Research on cutting height in soybean harvesting with a combine harvester. In IOP Conference Series: Earth and Environmental Science, Tashkent, Uzbekistan, 2023; 1112(1), pp. 012010. |

| [12] | Kurbanov, A., Shomirzaev, M., Tursunov, S., Toshbekov, O., Mukhamadieva, N., Kambarov, B. & Mannobova, S. Analysis of the state of cultivation and harvesting of mung bean and agro-biological requirements for threshing and separating its grain. In BIO Web of Conferences, Tashkent, Uzbekistan, 2024; 105, pp. 02010). |

| [13] | Unal, H., Isık, E., Izli, N., & Tekin, Y. Geometric and mechanical properties of mung bean (Vigna radiata L.) grain: Effect of moisture. International Journal of Food Properties, 2023, 11(3), 585-599. |

| [14] |

H. J. Singh, De. Dipankar, P. K. Sahoo. Physical properties of soybean cultivated inNEH region of India Agricultural Engineering International: CIGR Journal, Open access at http:

www.cigrjournal.org 2014, 1-5. |

| [15] | Pardayev O. R., Achilov E. T. Theortical study Process of separation of agricultural crops seeds from heand and pods under the influence of winders. Modern journal of social Sciences and humanities, Namangan, 2022, 36-41. |

APA Style

Temirovich, A. E. (2024). Development of a Device for Primary Purification of Mung Bean Grain from Pods and Optimization of Its Main Design Dimensions and Operating Modes. Engineering and Applied Sciences, 9(4), 63-68. https://doi.org/10.11648/j.eas.20240904.12

ACS Style

Temirovich, A. E. Development of a Device for Primary Purification of Mung Bean Grain from Pods and Optimization of Its Main Design Dimensions and Operating Modes. Eng. Appl. Sci. 2024, 9(4), 63-68. doi: 10.11648/j.eas.20240904.12

AMA Style

Temirovich AE. Development of a Device for Primary Purification of Mung Bean Grain from Pods and Optimization of Its Main Design Dimensions and Operating Modes. Eng Appl Sci. 2024;9(4):63-68. doi: 10.11648/j.eas.20240904.12

@article{10.11648/j.eas.20240904.12,

author = {Achilov Elyor Temirovich},

title = {Development of a Device for Primary Purification of Mung Bean Grain from Pods and Optimization of Its Main Design Dimensions and Operating Modes

},

journal = {Engineering and Applied Sciences},

volume = {9},

number = {4},

pages = {63-68},

doi = {10.11648/j.eas.20240904.12},

url = {https://doi.org/10.11648/j.eas.20240904.12},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.eas.20240904.12},

abstract = {It is important to create a technically and technologically improved device that reduces the damage to the mung during the process of removing the pods from the currently cultivated mung grain. Therefore, it is necessary to develop the design of the device, to justify its parameters and operating modes, for the complete separation and preliminary cleaning of mung beans without damaging them. The article presents the results of optimization of the main design dimensions and operating modes of the device for separating mung bean from the pods. The results of experimental studies showed that the proposed device has a high degree of completeness in separating mung bean from its pods and a low level of damage, low grain damage and high grain purity, which can be ensured with a sag length of 170 mm, a shaft oscillation number of 300 min-1, the amplitude of the shaft is 11.5 mm, its angle of inclination is 12 degrees. The design of the device for preliminary cleaning of mung grain by separating it from pods has been developed. The scientific significance of the research results is based on the structural dimensions and operating modes, as well as the resulting analytical connections and mathematical models, to ensure the quality of initial cleaning, to separate mung beans from pods completely and without damage, using less energy and resources. can be used to justify the parameters of similar devices. The developed device reduces the consumption of energy and labor during the initial cleaning of mung grain from pods, as well as the loss of grain.

},

year = {2024}

}

TY - JOUR T1 - Development of a Device for Primary Purification of Mung Bean Grain from Pods and Optimization of Its Main Design Dimensions and Operating Modes AU - Achilov Elyor Temirovich Y1 - 2024/08/27 PY - 2024 N1 - https://doi.org/10.11648/j.eas.20240904.12 DO - 10.11648/j.eas.20240904.12 T2 - Engineering and Applied Sciences JF - Engineering and Applied Sciences JO - Engineering and Applied Sciences SP - 63 EP - 68 PB - Science Publishing Group SN - 2575-1468 UR - https://doi.org/10.11648/j.eas.20240904.12 AB - It is important to create a technically and technologically improved device that reduces the damage to the mung during the process of removing the pods from the currently cultivated mung grain. Therefore, it is necessary to develop the design of the device, to justify its parameters and operating modes, for the complete separation and preliminary cleaning of mung beans without damaging them. The article presents the results of optimization of the main design dimensions and operating modes of the device for separating mung bean from the pods. The results of experimental studies showed that the proposed device has a high degree of completeness in separating mung bean from its pods and a low level of damage, low grain damage and high grain purity, which can be ensured with a sag length of 170 mm, a shaft oscillation number of 300 min-1, the amplitude of the shaft is 11.5 mm, its angle of inclination is 12 degrees. The design of the device for preliminary cleaning of mung grain by separating it from pods has been developed. The scientific significance of the research results is based on the structural dimensions and operating modes, as well as the resulting analytical connections and mathematical models, to ensure the quality of initial cleaning, to separate mung beans from pods completely and without damage, using less energy and resources. can be used to justify the parameters of similar devices. The developed device reduces the consumption of energy and labor during the initial cleaning of mung grain from pods, as well as the loss of grain. VL - 9 IS - 4 ER -