The outer covering of the rice grain, known as the rice husk, separates during the milling process. The rice husk is widely available and mostly considered a waste material that poses environmental and health risks if not properly managed. Despite not being the ideal feedstock due to its composition, however, rice husks can be effectively utilized as a renewable energy source by transforming them through a carbonized process and by compressed using a briquetting machine to create a stable, energy-dense product with enhanced properties, serving as a cost-effective and eco-friendly fuel source. Therefore, this study investigated the effect of clay soil binding agent ratio and compaction level on the physical properties of carbonized rice husk briquettes of the bulk density, moisture content, volatile matter, fixed carbon, and ash content at five levels of clay soil ratios: 0%, 5%, 10%, 15%, 20% and three levels of compaction level (6 mm, 12 mm, and 18 mm). The study implemented 5×3 factorial experiment in a completely randomized design with three replications and compared treatment means at a 95% level of significance. The result revealed that the bulk density ranged from 0.7795 to 1.3209 g/cm3, the moisture content ranged from 4.0207 to 5.0447%, the volatile matter ranged from 13.413 to 24.479%, the carbon fixed ranged from 50.492 to 68.269%, and the ash content ranged from 13.774 to 20.208%. In general, varying clay soil binding agent ratio and compaction pressure can enhance carbonized rice husk briquetting efficiency, enhancing storage efficiency, reducing transportation costs, decreasing ash residue, ensuring structural integrity, shape retention, and enhancing energy value. Future studies should explore alternative binder materials and different agricultural crop residues for carbonized briquetting, as well as examine thermal properties to understand combustion efficiency, heat generation capabilities, and economic feasibility.

| Published in | Bioprocess Engineering (Volume 9, Issue 1) |

| DOI | 10.11648/j.be.20250901.11 |

| Page(s) | 1-11 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Rice Husk, Clay Soil Binder, Compaction Pressure, Carbonized Rice Husk Briquetting, Physical Properties

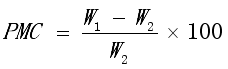

(1)

(1)  (2)

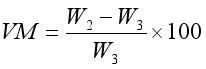

(2)  (3)

(3)  (4)

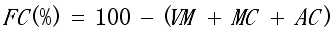

(4)  (5)

(5) AC | Ash Content |

ANOVA | Analysis of Variance |

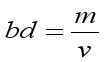

BD | Binding Ratio |

CP | Compaction Pressure |

FC | Fixed Carbon |

LSD | Least Significance Difference |

MC | Moisture Content |

VM | Volatile Matter |

| [1] | Adu-Poku, K. A., Appiah, D., Asosega, K. A., Derkyi, N. S. A., Uba, F., Kumi, E. N., Akowuah, E., Akolgo, G. A., & Gyamfi, D. (2022). Characterization of fuel and mechanical properties of charred agricultural wastes: Experimental and statistical studies. Energy Reports, 8, 4319–4331. |

| [2] | Ajimotokan, H. A., Ibitoye, S. E., Odusote, J. K., Adesoye, O. A., & Omoniyi, P. O. (2019). Physico-mechanical characterisation of fuel briquettes made from blends of corncob and rice husk. Journal of Physics: Conference Series, 1378(2), 22008. |

| [3] | Alahakoon, A. M. Y. W., Karunarathna, A. K., & Dharmakeerthi, R. S. (2018). Performance evaluation of a down draft double chamber pyrolysis reactor under field conditions. Tropical Agricultural Research, 30(1), 84. |

| [4] | Aliyu, M., Mohammed, I. S., Lawal, H. A., Dauda, S. M., Balami, A. A., Usman, M., Abdullahi, L., Abubakar, M., & Ndagi, B. (2021). Effect of compaction pressure and biomass type (rice husk and sawdust) on some physical and combustion properties of briquettes. ARID ZONE JOURNAL OF ENGINEERING, TECHNOLOGY AND ENVIRONMENT, 17(1), 61–70. |

| [5] | Ameen, A., Saeed, H., Harun, N. Y., Bilad, M. R., Afzal, M. T., Parvez, A. M., Amelia, F., Roslan, S., Rahim, S. A., Vinayagam, V. D., & Afolabi, H. K. (2021). Moisture Content Impact on Properties of Briquette Produced from Rice Husk Waste. |

| [6] | Anggraeni, S., Girsang, G. C. S., Nandiyanto, A. B. D., & Bilad, M. R. (2021). Effects of particle size and composition of sawdust/carbon from rice husk on the briquette performance. Journal of Engineering Science and Technology, 16(3), 2298–2311. |

| [7] | Anggraeni, S., Hofifah, S. N., Nandiyanto, A. B. D., & Bilad, M. R. (2021). Effects of particle size and composition of cassava peels and rice husk on the briquette performance. Journal of Engineering Science and Technology, 16(1), 527–542. |

| [8] | Aransiola, E. F., Oyewusi, T. F., Osunbitan, J. A., & Ogunjimi, L. A. O. (2019). Effect of binder type, binder concentration and compacting pressure on some physical properties of carbonized corncob briquette. Energy Reports, 5, 909–918. |

| [9] | Bakari, M. I. Y. (2016). Characterization of rice husks as a biofuel feedstock towards sustainable rural rice processing in Sub-Saharan Africa. McGill University (Canada). |

| [10] | Celestino, J. M. T., Lating, P. O., Nabuuma, B., & Yiga, V. A. (2023a). Effects of clay, gum Arabic and hybrid binders on the properties of rice and coffee HUSK briquettes. Results in Engineering, 20(October), 101488. |

| [11] | Celestino, J. M. T., Lating, P. O., Nabuuma, B., & Yiga, V. A. (2023b). Effects of clay, gum Arabic and hybrid binders on the properties of rice and coffee HUSK briquettes. Results in Engineering, 20, 101488. |

| [12] | Chukwuneke, J., Umeji, A., Obika, E., & Fakiyesi, O. (2021). Optimization of composite briquette made from sawdust/rice husk using starch and clay binder. International Journal of Integrated Engineering, 13(4), 208–216. |

| [13] | Daniel, K. K., Siagi, Z. O., & Ogola, J. O. (2020). Effect of formulation, binder and compaction pressure of rice husk-bagasse briquettes on thermal and physical properties. Journal of Scientific Research and Reports, 26(10), 38–53. |

| [14] | Demirel, B. (2023). Determination of solid biofuel properties of hazelnut husk briquettes obtained at different compaction pressures. Biomass Conversion and Biorefinery, 13(14), 13267–13278. |

| [15] | Deshannavar, U. B., Hegde, P. G., Dhalayat, Z., Patil, V., & Gavas, S. (2018). Production and characterization of agro-based briquettes and estimation of calorific value by regression analysis: An energy application. Materials Science for Energy Technologies, 1(2), 175–181. |

| [16] | Efomah, A. N., & Gbabo, A. (2015). The Physical, Proximate and Ultimate Analysis of Rice Husk Briquettes Produced from a Vibratory Block Mould Briquetting Machine. 2(5), 814–822. |

| [17] | Elinge, C. M., Birnin-Yauri, A. U., Senchi, D. S., Ige, A. R., Ajakaye, J., Yusuf, A., & Abubakar, R. K. (2019). Studies on the combustion profile of briquettes produced from carbonized rice husk using different binders at moderate temperature and die pressure. Int. J. Adv. Acad. Res, 5, 70–77. |

| [18] | Gao, Y., Guo, X., Liu, Y., Fang, Z., Zhang, M., Zhang, R., You, L., Li, T., & Liu, R. H. (2018). A full utilization of rice husk to evaluate phytochemical bioactivities and prepare cellulose nanocrystals. Scientific Reports, 8(1), 10482. |

| [19] | Ghesti, G. F., Silveira, E. A., Guimarães, M. G., Evaristo, R. B. W., & Costa, M. (2022). Towards a sustainable waste-to-energy pathway to pequi biomass residues: Biochar, syngas, and biodiesel analysis. Waste Management, 143, 144–156. |

| [20] | Ikelle, I. I., Chukwuma, A., & Philip Ivoms, O. S. (2014). The Characterization of the Heating Properties of Briquettes of Coal and Rice Husk. IOSR Journal of Applied Chemistry, 7(5), 100–105. |

| [21] | Inegbedion, F., & Ikpoza, E. (2022). Estimation of the Moisture Content, Volatile Matter, Ash Content, Fixed Carbon and Calorific Values of Rice Husk Briquettes. June. |

| [22] | Jani, S. M. (2016). The proximate analysis and mechanical properties of rice husk charcoal briquette. |

| [23] | Kipngetich, P., Kiplimo, R., Tanui, J. K., & Chisale, P. (2023). Effects of carbonization on the combustion of rice husks briquettes in a fixed bed. Cleaner Engineering and Technology, 13(February), 100608. |

| [24] | Kofa, S. &. (2020). PROXIMATE AND ULTIMATE ANALYSIS OF CARBONIZED RICE. 6(10), 120–128. |

| [25] | Kordi, M., Farrokhi, N., Pech-Canul, M. I., & Ahmadikhah, A. (2024). Rice Husk at a Glance: From Agro-Industrial to Modern Applications. Rice Science, 31(1), 14–32. |

| [26] | Koskin, A. P., Zibareva, I. V, & Vedyagin, A. A. (2020). Conversion of rice husk and nutshells into gaseous, liquid, and solid biofuels. Biorefinery of Alternative Resources: Targeting Green Fuels and Platform Chemicals, 171–194. |

| [27] | Kpalo, S. Y., Zainuddin, M. F., Manaf, L. A., & Roslan, A. M. (2020). A review of technical and economic aspects of biomass briquetting. Sustainability, 12(11), 4609. |

| [28] | Lin, K. S., Wang, H. P., Lin, C., & Juch, C. (1998). A process development for gasification of rice husk. January 1996, 185–192. |

| [29] | Lubwama, M., Yiga, V. A., & Lubwama, H. N. (2022a). Effects and interactions of the agricultural waste residues and binder type on physical properties and calorific values of carbonized briquettes. Biomass Conversion and Biorefinery, 12(11), 4979–4999. |

| [30] | Lubwama, M., Yiga, V. A., & Lubwama, H. N. (2022b). Effects and interactions of the agricultural waste residues and binder type on physical properties and calorific values of carbonized briquettes. Biomass Conversion and Biorefinery, 12(11), 4979–4999. |

| [31] | Lubwama, M., Yiga, V. A., Muhairwe, F., & Kihedu, J. (2020). Physical and combustion properties of agricultural residue bio-char bio-composite briquettes as sustainable domestic energy sources. Renewable Energy, 148, 1002–1016. |

| [32] | Maes, W. H., & Verbist, B. (2012). Increasing the sustainability of household cooking in developing countries: policy implications. Renewable and Sustainable Energy Reviews, 16(6), 4204–4221. |

| [33] | Narzary, A., Brahma, J., & Das, A. K. (2023). Utilization of waste rice straw for charcoal briquette production using three different binder. Cleaner Energy Systems, 5(June). |

| [34] | Nazari, M. M., Idroas, M. Y., & Ayuni, F. A. (2020). Carbonization effect on EFB briquettes prepared with different type of binders. IOP Conference Series: Earth and Environmental Science, 476(1), 12072. |

| [35] | Ndindeng, S. A., Mbassi, J. E. G., Mbacham, W. F., Manful, J., Graham-Acquaah, S., Moreira, J., Dossou, J., & Futakuchi, K. (2015). Quality optimization in briquettes made from rice milling by-products. Energy for Sustainable Development, 29, 24–31. |

| [36] | Ngene, G. I., Bouesso, B., GONZÁLEZ, M., & Nzihou, A. (2024). A review on biochar briquetting: Common practices and recommendations to enhance mechanical properties and environmental performances. Journal of Cleaner Production, 143193. |

| [37] | Obi, O. F., Pecenka, R., & Clifford, M. J. (2022). A review of biomass briquette binders and quality parameters. Energies, 15(7), 2426. |

| [38] | Olugbade, T., Ojo, O., & Mohammed, T. (2019). Influence of binders on combustion properties of biomass briquettes: a recent review. BioEnergy Research, 12, 241–259. |

| [39] | Pode, R., Diouf, B., & Pode, G. (2015). Sustainable rural electrification using rice husk biomass energy: A case study of Cambodia. Renewable and Sustainable Energy Reviews, 44, 530–542. |

| [40] | Saad, M. J., & Jani, S. M. (2016). The proximate analysis and mechanical properties of rice husk charcoal briquette. J. Trop. Agric. and Fd. Sc, 44(2), 243–251. |

| [41] | Sam Obu, C. V, Amos, J., Chris-Ukaegbu, S. O., Dike Chijindu, P., & Odeniyi, O. M. (2022). Production of Fuel Briquettes from a Blend of Corncob and Rice Husk. International Journal of Research and Review, 9(2), 349–978. |

| [42] | Scheurlen, E. (2015). Time allocation to energy resource collection in rural Ethiopia: Gender-disaggregated household responses to changes in firewood availability. |

| [43] | Shiferaw, Y., Tedla, A., Melese, C., Mengistu, A., Debay, B., Selamawi, Y., Merene, E., & Awoi, N. (2017). Preparation and evaluation of clean briquettes from disposed wood wastes. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 39(20), 2015–2024. |

| [44] | Singh, S., Kaur, G., Singh, D. P., Arya, S., & Krishania, M. (2024). Exploring rice straw’s potential from a sustainable biorefinery standpoint: Towards valorization and diverse product production. Process Safety and Environmental Protection. |

| [45] | Sunnu, A. K., Adu-Poku, K. A., & Ayetor, G. K. (2023). Production and characterization of charred briquettes from various agricultural waste. Combustion Science and Technology, 195(5), 1000–1021. |

| [46] | Suryaningsih, S., Nurhilal, O., Yuliah, Y., & Salsabila, E. (2018). Fabrication and characterization of rice husk charcoal bio briquettes. AIP Conference Proceedings, 1927(February). |

| [47] | Tanko, J., Ahmadu, U., Sadiq, U., & Muazu, A. (2021). Characterization of rice husk and coconut shell briquette as an alternative solid fuel. Advanced Energy Conversion Materials, 1–12. |

| [48] | Teko, G. N., Nji, C., Endeley, J. B., & Laar, A. (2016). Gender assessment of hazard exposure, risk awareness and cultural perceptions associated with firewood usage: A case study of Mendakwe village in Cameroon. International Research Journal of Public and Environmental Health. |

| [49] | Yusuf, M. A., Witdarko, Y., Parjono, Pamungkas, W. A., & Suryadi. (2023). Characteristics of Charcoal Briquettes from Rice Husk Waste with Compaction Pressure Variations as an Alternative Fuel. Journal of Ecological Engineering, 24(4), 237-–243. |

APA Style

Fetene, M. A., Tikuneh, D. B. (2025). The Effect of Clay Soil Binding Agent Ratio and Compaction Pressure Level on the Physical Properties of Carbonized Rice Husk Briquettes. Bioprocess Engineering, 9(1), 1-11. https://doi.org/10.11648/j.be.20250901.11

ACS Style

Fetene, M. A.; Tikuneh, D. B. The Effect of Clay Soil Binding Agent Ratio and Compaction Pressure Level on the Physical Properties of Carbonized Rice Husk Briquettes. Bioprocess Eng. 2025, 9(1), 1-11. doi: 10.11648/j.be.20250901.11

@article{10.11648/j.be.20250901.11,

author = {Mersha Alebachew Fetene and Dessye Belay Tikuneh},

title = {The Effect of Clay Soil Binding Agent Ratio and Compaction Pressure Level on the Physical Properties of Carbonized Rice Husk Briquettes},

journal = {Bioprocess Engineering},

volume = {9},

number = {1},

pages = {1-11},

doi = {10.11648/j.be.20250901.11},

url = {https://doi.org/10.11648/j.be.20250901.11},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.be.20250901.11},

abstract = {The outer covering of the rice grain, known as the rice husk, separates during the milling process. The rice husk is widely available and mostly considered a waste material that poses environmental and health risks if not properly managed. Despite not being the ideal feedstock due to its composition, however, rice husks can be effectively utilized as a renewable energy source by transforming them through a carbonized process and by compressed using a briquetting machine to create a stable, energy-dense product with enhanced properties, serving as a cost-effective and eco-friendly fuel source. Therefore, this study investigated the effect of clay soil binding agent ratio and compaction level on the physical properties of carbonized rice husk briquettes of the bulk density, moisture content, volatile matter, fixed carbon, and ash content at five levels of clay soil ratios: 0%, 5%, 10%, 15%, 20% and three levels of compaction level (6 mm, 12 mm, and 18 mm). The study implemented 5×3 factorial experiment in a completely randomized design with three replications and compared treatment means at a 95% level of significance. The result revealed that the bulk density ranged from 0.7795 to 1.3209 g/cm3, the moisture content ranged from 4.0207 to 5.0447%, the volatile matter ranged from 13.413 to 24.479%, the carbon fixed ranged from 50.492 to 68.269%, and the ash content ranged from 13.774 to 20.208%. In general, varying clay soil binding agent ratio and compaction pressure can enhance carbonized rice husk briquetting efficiency, enhancing storage efficiency, reducing transportation costs, decreasing ash residue, ensuring structural integrity, shape retention, and enhancing energy value. Future studies should explore alternative binder materials and different agricultural crop residues for carbonized briquetting, as well as examine thermal properties to understand combustion efficiency, heat generation capabilities, and economic feasibility.},

year = {2025}

}

TY - JOUR T1 - The Effect of Clay Soil Binding Agent Ratio and Compaction Pressure Level on the Physical Properties of Carbonized Rice Husk Briquettes AU - Mersha Alebachew Fetene AU - Dessye Belay Tikuneh Y1 - 2025/01/14 PY - 2025 N1 - https://doi.org/10.11648/j.be.20250901.11 DO - 10.11648/j.be.20250901.11 T2 - Bioprocess Engineering JF - Bioprocess Engineering JO - Bioprocess Engineering SP - 1 EP - 11 PB - Science Publishing Group SN - 2578-8701 UR - https://doi.org/10.11648/j.be.20250901.11 AB - The outer covering of the rice grain, known as the rice husk, separates during the milling process. The rice husk is widely available and mostly considered a waste material that poses environmental and health risks if not properly managed. Despite not being the ideal feedstock due to its composition, however, rice husks can be effectively utilized as a renewable energy source by transforming them through a carbonized process and by compressed using a briquetting machine to create a stable, energy-dense product with enhanced properties, serving as a cost-effective and eco-friendly fuel source. Therefore, this study investigated the effect of clay soil binding agent ratio and compaction level on the physical properties of carbonized rice husk briquettes of the bulk density, moisture content, volatile matter, fixed carbon, and ash content at five levels of clay soil ratios: 0%, 5%, 10%, 15%, 20% and three levels of compaction level (6 mm, 12 mm, and 18 mm). The study implemented 5×3 factorial experiment in a completely randomized design with three replications and compared treatment means at a 95% level of significance. The result revealed that the bulk density ranged from 0.7795 to 1.3209 g/cm3, the moisture content ranged from 4.0207 to 5.0447%, the volatile matter ranged from 13.413 to 24.479%, the carbon fixed ranged from 50.492 to 68.269%, and the ash content ranged from 13.774 to 20.208%. In general, varying clay soil binding agent ratio and compaction pressure can enhance carbonized rice husk briquetting efficiency, enhancing storage efficiency, reducing transportation costs, decreasing ash residue, ensuring structural integrity, shape retention, and enhancing energy value. Future studies should explore alternative binder materials and different agricultural crop residues for carbonized briquetting, as well as examine thermal properties to understand combustion efficiency, heat generation capabilities, and economic feasibility. VL - 9 IS - 1 ER -